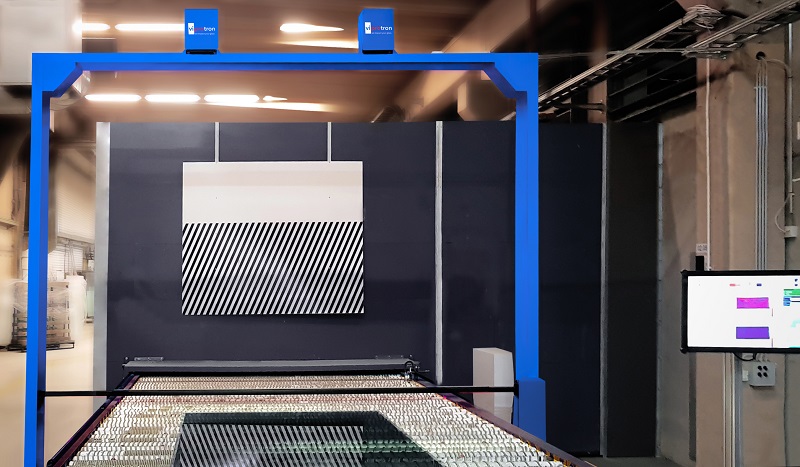

Anisotropies, also known as iridescence, present as dark circles, spots, or stripes in the glass that are visible in polarized light, from certain angles or through polarized sunglasses. The visual effect is caused by different tensions in the glass, mostly resulting from the tempering process.

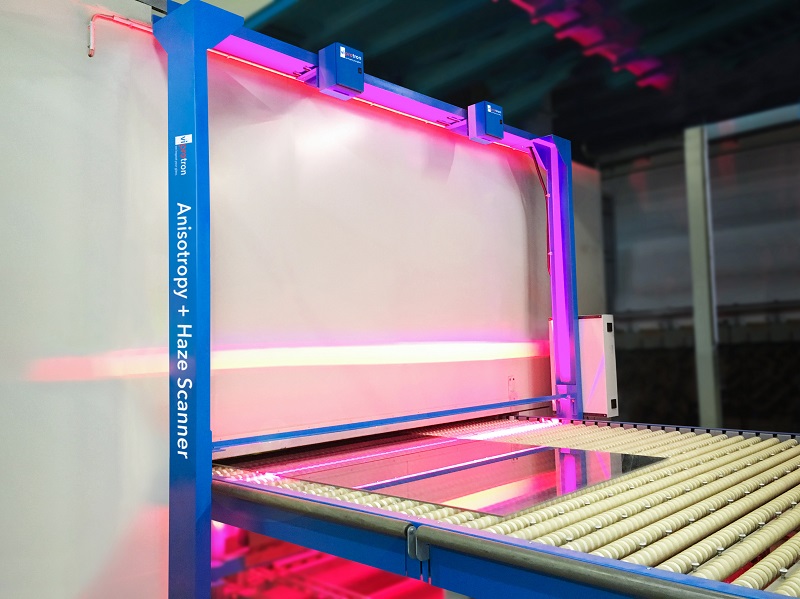

As an option in addition to measuring anisotropies, the scanner can detect white haze on the glass, which can be caused by dust, rollers, or other factors in the furnace. The haze detection allows operators to know exactly where they must rework the glass to ensure a clean surface before sending it to the next processing stage or the customer.

The Anisotropy Scanner is measuring without causing a production delay up to a production speed of 25 m/min. Anisotropies are visualized as a batch coming from the oven bed. Each single glass on the batch is measured and the corresponding anisotropy value is displayed and documented. So, there is a proof that the minimal target value is achieved at each glass.