Date: 4 February 2013

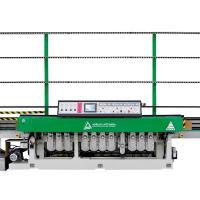

The currently produced models of vertical washing machines are 3 and they can be included in edging and bevelling lines, also thanks to the possibility to have the working surface at the same height.

On request it is possible to manage thickness and speed adjustments ‘in-line’.

Washing machine model OT 1600/400/4S in-line with our edging machine model TL 11 AV

The first two model (OT 1600/400/4S and OT 2000/400/4S) differ from each other only for the working height for the washing, all other technical features are the same. They are open top vertical washing and drying machines for glasses with a thickness from 3 up to 20 mm (on request 40 mm) and with minimum dimensions of 350 mm. The body of the machine and all the parts in contact with the water are made of stainless steel while an anti-corrosion covering is granted by the use of epoxy and polyurethane paints.

The machines are composed of two different washing sections, equipped in total with four brushes which can also be available in the special version for low-e coated glasses. In the first section can be also required hot water. The drying is done by a couple of blowers powered by a high-pressure soundproof ventilator. The inlet and outlet conveyors are motorized like the glass thickness adjustment by guaranteeing in this way a better washing quality on every thickness. On the conveyors is possible set up belts instead of the standard rolls: in this way is facilitated the loading of small glasses, round or in shape glasses. In the outlet side is possible put on a black panel with inspection lamps, to facilitate the control of the cleanliness degree of the glass sheet.

As additional security, both models are equipped with a sensor, positioned on the outlet conveyor and connected to an acoustic alarm, with the function of detecting the presence of the glass sheet at the end of the rack. In order to obtain energy savings, they can be also equipped with an additional sensor, positioned on the inlet conveyor, which by detecting the presence of the glass sheet at the entrance side of the machine, reactivates some functions in stand-by mode.

Washing machine model OT 300

The third of the produced models (OT 1600/200/4S) is an 'economic' version, the main differences compared to the models described above, are two: manual speed change and fixed glass thickness from 3 up to 15 mm. During the storage of the glass it can happen to incur the risk of causing scratches on the glass sheets because of the dirt settled during the processing, especially if the glass sheet is polished by liquid cerium oxide.

Furthermore, the no-removal in a short time of these residues can cause difficulties in the following cleaning phases, especially in case of special glasses, such as for example satin glass. This problem can be solved thanks to the use of the small OT 300 that fitted on the outlet conveyor of grinding and bevelling machines allows a complete cleaning and drying of the processed edges of the glass sheets. The OT 300 is also available in a motorized version, able to automatically position itself according to the glass thickness set on the machine. Equipped with two brushes, it is possible to request the version for the washing of low-e coated glasses. Always on demand, the hot water option can also be chosen.

Add new comment