Pfarrwald 45

Wolfsbach 3354

Austria

Systron GmbH

We are convinced of that. That is why we combine our extensive knowledge of the flat glass industry with a lot of commitment every day. We work together to develop extraordinary solutions for vertical glass processing.

systron was founded in 2014 by Franz Schachner and Reinhard Gruber with the aim of offering our customers extremely durable, easily accessible and quickly serviceable machines. Our successful development that we are heading in the right direction with our philosophy. Some of the most well-known companies in the flat glass industry rely on systron.

Products

Our proHD glass processing centre with integrated waterjet technology is the most flexible all-in-one solution with the smallest footprint on the market.

A huge variety of applications:

- Seaming, milling, sinking, grinding and polishing outer and inner contours

- Drilled holes and cutouts using our patented waterjet technology

- Clamping once for all interior and exterior processing with minimal machining tolerances

The proHD is exactly the right choice for glass with complex shapes and cut-outs. The flexible system enables an efficient and particularly economical processing, especially for difficult processes and batch sizes of 1.

SYSTRON SETS NEW STANDARDS IN CNC GLASS PROCESSING

- One time clamping for all interior and exterior machining

- Minimal machining tolerances, max. +/- 0.2 mm on the entire product size

- Maximum flexibility regarding contours and special shapes

- No set-up times between different glass thicknesses and types

- Very rigid, vibration-free construction allows highest processing quality also at oblique edges or radii

THE MOST DIFFICULT TASKS CAN BE EASILY MASTERED

Up to 4000 bar pressure water jet allows extremely fast cutting of all inner- and outer contours with even complex geometries with highest precision.

All kinds of processing with one machine – with highest precision!

The waterjet technology enables shortest cycle times. High quality waterjet cut contours can be toughened without post-processing. A reduction of production time up to 50% is possible.

FIND OUT MORE:

HIGHLIGHTS

- Constant polishing quality by precisely controlled polishing pressure

- Vibration-free machining prevents chipping

- Arris parallelism guaranteed by patented water-cushion guidance

- High pressure tool cooling over the entire tool circumference

- Automatic positioning of the glass sheets, also for special shapes

- Low maintenance costs of the high pressure unit by new / patented systems

- Continuously protected suction cups

- No mechanical contact at machining coated glass surfaces

- Intuitive graphical machine interface enables easy operation of the system

systron pro is a vertical CNC processing centre for contours specially on the outside. Grinding and polishing of contours can be done with the highest precision and short lead time due to the solid construction and use of our patented systems. A barrier-free design allows the operator an ergonomically optimal working position and easy access to all machine components.

Outer contours in perfection:

- Grinding of outer contours

- Polishing of outer contours

- EXACT DIMENSIONS GUARANTEED

SYSTRON SETS NEW STANDARDS IN CNC GLASS PROCESSING

- One time clamping for all interior and exterior machining

- Minimal machining tolerances, max. +/- 0.2 mm on the entire product size

- Maximum flexibility regarding contours and special shapes

- No set-up times between different glass thicknesses and types

- Very rigid, vibration-free construction allows highest processing quality also at oblique edges or radii

VERTICAL GLASS-PROCESSING IN PERFECTION

The processing spindle ensures an optimal grinding and polishing image. 2 tools can be mounted per tool holder. The spindle offers ample power reserves for all kinds of processing.

Patented process

The patented water cushion follows the glass surface and ensures continuous tool cooling.

FIND OUT MORE:

HIGHLIGHTS

- Constant polishing quality by precisely controlled polishing pressure

- Vibration-free machining prevents chipping

- Arris parallelism guaranteed by patented water-cushion guidance

- High pressure tool cooling over the entire tool circumference

- Automatic positioning of the glass sheets, also for special shapes

- Continuously protected suction cups

- No mechanical contact at machining coated glass surfaces

- Intuitive graphical machine interface enables easy operation of the system

Our systron HD is a vertical glass processing machine, for cutouts and interior contours, with integrated high-pressure water jet technology.

Precision & speed for internal machining:

- Holes and cutouts using patented high pressure technology

- Bilateral counter-sinking using Helix method

- No limitation on contours and special shapes

- Suitable for use as Stand-Alone Machine or Two-Tower Solution

SYSTRON SETS NEW STANDARDS IN CNC GLASS PROCESSING

- The waterjet cut-outs are ready for tempering without post processing

- Reduction of production time up to 50%

- No limitation on contours and special shapes

- Waterjet up to 4000 bar

- Very rigid, vibration-free construction allows highest processing quality also at oblique edges of radii

PATENTED WATERJET CUTTING TECHNOLOGY

Up to 4000 bar pressure water jet allows extreme fast cutting of all inner- and outer contours with even complex geometries with highest precision.

Highest precision & short cycle times

The waterjet technology enables shortest cycle times. High quality waterjet cut contours can be toughened without post-processing. A reduction of production time up to 50% is possible.

HIGHLIGHTS

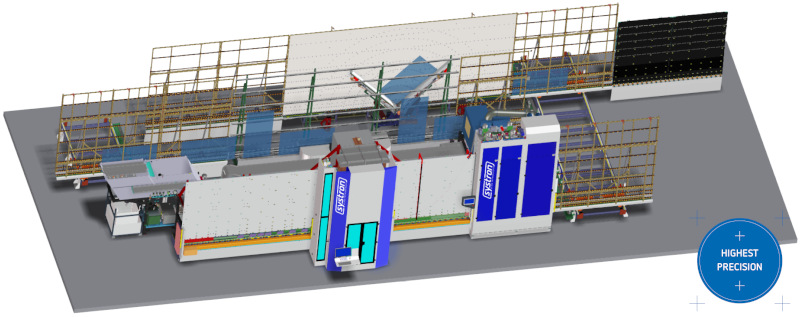

- A shared transport system ensures a continuous production flow.

- Throughput is maximised by minimal machine idle times.

- Our patented process fixes the glass without any mechanical contact and optimally cooles the tool at its full circumference.

- Front and rear heavy-duty spindles for precise internal machining

- The counter-sinking of large cutouts is done by helix method without time-consuming tool changes

- Tiltable suction cups – only the required ones are tilted out of the protected area

- Intuitive graphical machine interface enables easy operation of the system

Due to the rigid machine design, machining of contours, inside and outside radii can be performed with shortest cycle times. Patented systems are assuring the highest edge quality.

SEAMING AND GRINDING CAN BE PERFORMED WITHOUT TOOL EXCHANGE

- Edge grinding and seaming

- Corner dubbing without cycle time loss

- Automatic sheet measurement

NEW STANDARDS FOR SEAMING AND GRINDING GLASS CONTOURS

- Grinding head follows the glass contour also in case of unequal breakage

- Floating tool spindle

- Optional 1 or 2 grinding spindles

- Glass thicknesses 4 – 19 mm without tool exchange

TOP QUALITY AT EXTREMELY HIGH GRINDING SPEED

- Edge grinding and seaming can be performed without tool exchange

- Corner dubbing at maximum seaming speed

- Max. grinding speed 30 m/min.

FIND OUT MORE:

HIGHLIGHTS

- No mechanical contact during processing coated glass

- Automatic sheet measurement for rectangular panes

- Tool package width up to 58 mm

- Various tool profiles possible

- Flexible processing spindle is self-adapting to the grinding contour

- Torque control of the machining spindle

- Easy processing of complex shapes

- Tool diameter 200 mm

The glass passes through four rounds on the straight-line edger by automatically rotating 90° each pass. Grinding and polishing are carried out with 11 spindles with cup wheels. Even large and heavy special shapes can be processed very efficiently using very little floor space with the systron LOOP.

In order to be able to manufacture dimensionally accurate and angularly precise products with internal machining, the combination with the systron proHD glass processing centre is recommended. The two systems can also be operated independently of each other.

SYSTRON INTRODUCES NEW STANDARDS

- Premium straight line edging machine with 11 spindles

- Servo-controlled spindle feed & polishing pressure control

- Corner dubbing by a circumferential tool

- Integrated bottom edge washing machine

DIGITAL TWIN: FROM REALITY TO VIRTUALITY

The intuitive machine software is clearly displayed on a multi-touch panel. A new operating concept allows fast and accurate axis positioning in manual mode.

An exact reflection by means of a digital twin with the real time view on the operator terminal enables easy operation and overview.

LOOP HIGHLIGHTS

- Machining of straight special shapes with cup wheel polishing

- No set-up times for different glass dimensions

- Simple and reliable transport system

- High polishing quality due to constant, servo-controlled polishing pressure

- Easy to adapt to the available space thanks to the modular design

- Flexible and strong turning unit for large and heavy special shapes

LOOP PROHD COMBO TRUE TO SIZE & ANGLE

with brilliant cup wheel polish

LOOP PROHD COMBO HIGHLIGHTS

- Cup Wheels – Grind & Polish

- Pre-grinding true to size and internal machining of any kind

- Very short cycle times with small batch sizes

- High dimensional and angular accuracy, even with straight special shapes

- Vertical, space-saving design

- Possibility of machining complex CNC glass with proHD (bypass)

FIND OUT MORE:

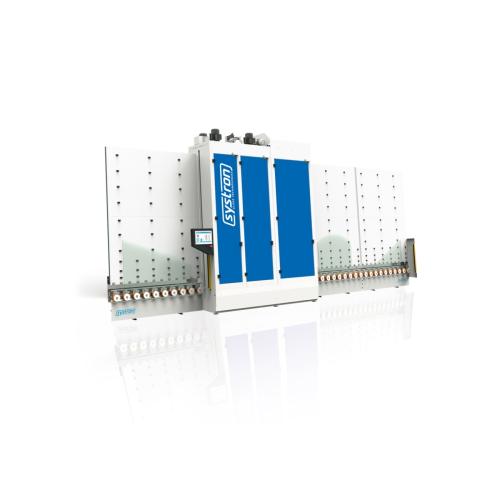

Due to the solid construction, the use of high-quality components and the special transport system, this washing station is especially designed for Low-E glass.

NEW STANDARD FOR WASHING FLOAT AND COATED GLASS

The washing section is divided in two zones, pre-wash and main wash zone.

The pre-wash zone is equipped with one pair of brushes and four spray tubes.

The main wash zone is equipped with two brush pairs and four spray tubes.

AUTOMATIC ADJUSTMENT TO THE GLASS THICKNESS WITHOUT LOSS OF CYCLE TIME

- Washing speed up to 10m/min

- Intuitive graphical machine interface enables easy operation of the system

Drying zone

The drying zone, which the glass is passing through in the last step, is equipped with a high-performance blower and ensures a crystal-clear visibility and guarantees a dry result.

FIND OUT MORE:

HIGHLIGHTS

- Machine body and doors made of stainless steel, so no corrosion can occur

- Completely enclosed system protected from sunlight (no algae formation)

- 6 Low-E brushes in 2 washing zones

- Special transport system: No mechanical contact with glass coatings

- Complete drive technology in the dry area of machine roof

- Two water tanks each with an integrated heating element of 6kW