Others also read

| In August 2013, the LiSEC development team started a major project with the mission: redesign of the tempering furnaces in order to save manufacturing costs and at the same time increase the process reliability. Result: the AEROFLAT.

| “Thank you for all the services your company has provided for us. We really appreciate all, the great installation and startup of the RC200™. We are very happy with the outcome of our new furnace.”

| Furnaces are currently inspected on a regular basis with thermal imaging sensors and other techniques that heavily rely on experience of the plant personnel.

| “UniGlass is committed to stay at the forefront of the technological trends. We want to make sure we can offer our customers the total range of glass products that they need for their projects.”

| A More Sustainable Approach for Future Façades

| For the past five years, Nile Aluminium & Metals Company, or AluNile, has had very positive experiences with Glaston's first FC500™ tempering furnace sold outside Finland.

| Being highly focused on flat glass processes for partitioning used in the office industry, Tufwell Glass Ltd has carved out a unique and resilient position for itself in southeast region of England.

| After 10 years of experience with the Glaston HTF 2142 furnace, Paul Buckley, Managing Director of the PJB Glass Group, decided to complement his flat glass production offering by investing in a Glaston RC200™ furnace.

| The Flachglas Group employs around 1,100 employees at three sites in Switzerland and three sites in Germany – around 650 of them generate revenues of approx. € 70 million at the Wernberg site (Bavaria).

| Sanshiba Shozai of Japan chose to be the first glass processor in the world to invest in Glaston’s latest GlastonInsight™,the intelligent online assistance system, at the same time as it ordered the Glaston RC350™ tempering furnace.

| To understand how sound insulation works for windows and framing it is important to understand how sound itself travels and transmits.

| Melting glass is a very energy intensive process, with process temperatures of more than 1600°C required to melt the raw materials in the furnace.

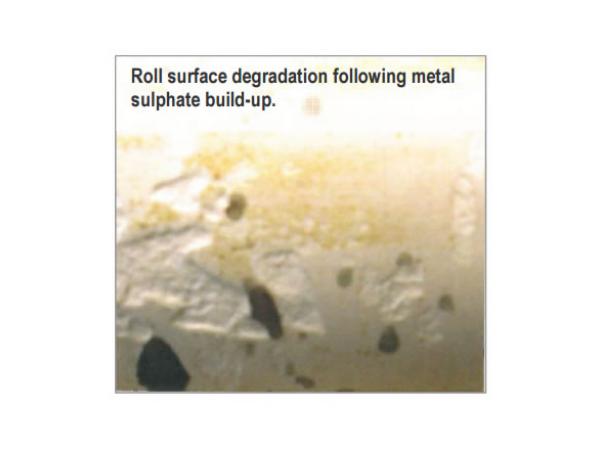

| Even If float technology has been developed and explored in details, the requirement of new and more aggressive glasses is incremental to the expected length of float sequences.

| Fused silica rollers are widely used to convey glass in high temperature environments, the tempering furnace being among the most demanding operations.

| Despite increasingly demanding requirements to save energy and a focus on reducing our use of prime energy, we also need to bear in mind economics and cost effectiveness during the construction phase of buildings, especially on larger projects.

| The following approach describes a new encapsulation technology for glass-glass-modules using tempered thin glass as front and back sheets.

| At this year's GPD in Finland LiSEC was represented by two lecturers.

| The most recent technical development from LiSEC is that of a brand-new laminating tunnel, which was installed at one of its Italian clients’ plants late in 2010.

| Forehearth operation is simple – you just set the temperatures you need on the zone controllers and away you go. In fact, it is so easy that the production department can attend to it alongside their real job of running the machine.

| Wrightstyle Limited is one of the UK’s most innovative steel glazing specialists with an international client base. Lee Coates, the company’s technical manager, explains the mechanics of fire and fire safety.

| The oscillating horizontal tempering furnace developed in the 1970s has been one of the most significant innovations of recent decades, above all commercially.