Others also read

| Global environmental concern is motivating efforts to improve energy efficiency in all industrial sectors. And glass tempering is no exception.

| Today, almost all new devices – from home appliances to production equipment – are connected. Rapid development in consumer electronics has been increasingly moving towards industrial use. In the glass industry, this development is still in its early stages.

| To really succeed in glass lamination, it takes much more than just having the best equipment – it’s about understanding the process in and out.

| Glass production is an energy-intensive process by its nature, so even small reductions there can result in considerable savings in energy and costs.

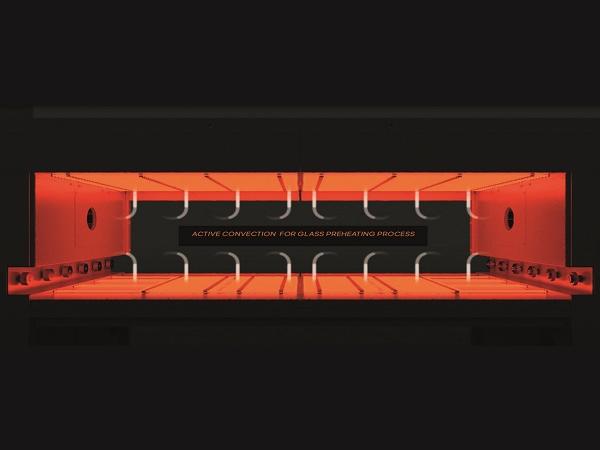

| Full convection, forced convection, focused convection, recirculated convection – the list of terms goes on and on.

| We all know that glass lamination is the process of bonding two or more panes of glass with a flexible interlayer in between. Sounds simple. But is it always so in practice?

| I want you to think about your daily journey to work. Take a minute, visualize it – and then answer me this: How many glass surfaces did you see? Too many to remember?

| Limiting global warming require “rapid and far-reaching” transitions in land, energy, industry, buildings, transport, and cities.

| Bent and tempered glass has long been of great interest to the market. The process of creating high-quality tempered bent glass has evolved over the years.

| Do you still spend precious time doing the meticulous task of manually counting glass cullets for a glass fragmentation test? Or maybe your modern counting tool is not exactly the gold standard? If so, we have some good news for you!

| The latest Glastory blog is dealing with the newest trends coming to the bus glass market - how the cut-outs, digital and screen printing, larger surfaces and thinner glass to reduce weight and fuel consumption is challenging the glass processing.

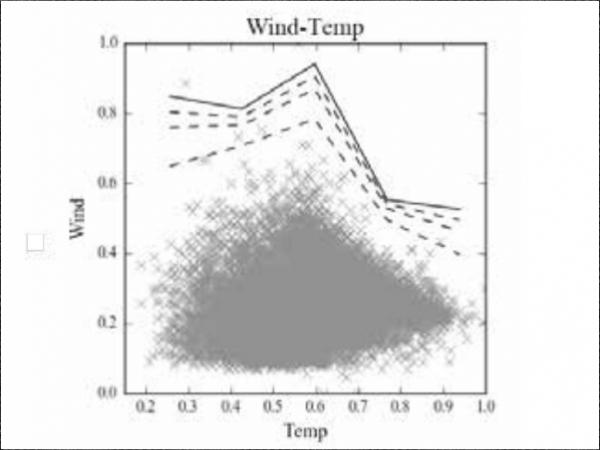

| An Initial Study Towards Optimized Structural Assessment of Glass Components

| The latest Glastory post is dealing with the trends in automotive display glass processing.

| In this blog post, we look at trends in the sunroof and windshield business today and how glass processors can prepare for them.

| A clean, safe and sustainable source of energy, solar continues to power the world at a faster pace than ever before.

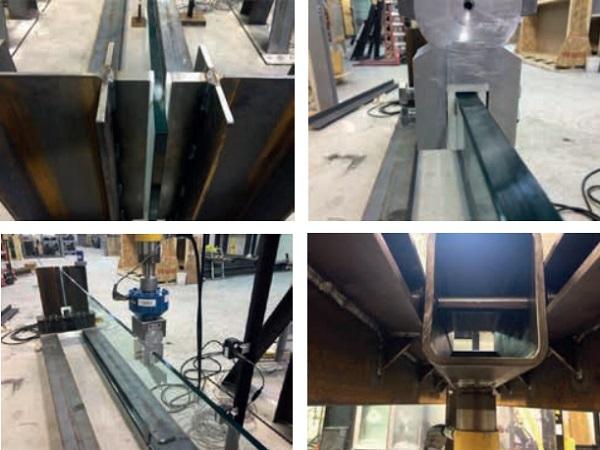

| Building code requirements for wind-borne debris protection have been in existence since the mid- 1990s, and as a result, many glazing systems have been tested and certified to these performance requirements.

| For nearly 50 years, glass has been used as structural elements in glass fin applications. These applications include interior and exterior projects, supporting facades, canopies, storefronts, curtain walls and skylights.

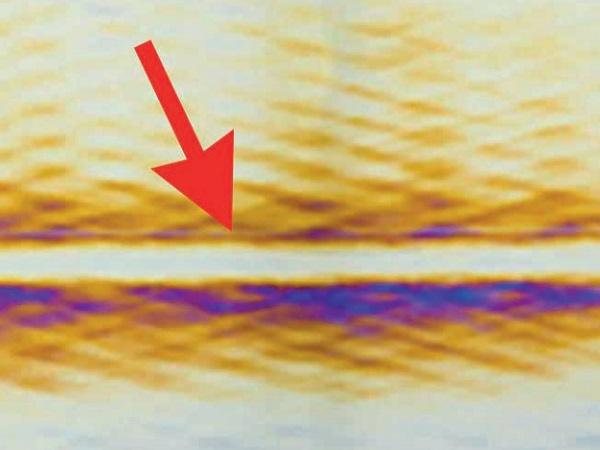

| Anisotropy is the term used in the façade industry to describe the manifestation of patterns and colourful areas in heat-treated glass under certain light and viewing conditions.

| Latest Glastory blog by Jukka Immonen is dealing with the 5 promises of convection technology in windshield bending.

| The structural glass for this globe structure is created with laminated double curved glass panels patch supported by a steel structure.

| Data-based business models are also becoming increasingly relevant to the glass industry.

| Some practical tips on how you can well maintain your laminating line and extend its longevity.

| Glaston is working hard to make tempering furnaces more automated.

| That’s an excellent question! It really is true that SentryGlass is more difficult to laminate in many aspects than standard PVB. But if we first think of what SentryGlass has been designed for, it is to give structural strength to the laminate.

| It is a very known behavior that the glass fragmentation depends on where you break the glass.