Date: 21 July 2017

A riveting and timely discussion between host Paul Beers and his guest Mike Buchholz of Tremco, covering a wide range of issues related to waterproofing, is now available on the “Everything Building Envelope” podcast.

Mike Buchholz has been with Tremco since 2003 and is currently a regional district manager in the Commercial Sealants and Waterproofing division; prior to this position, Mike worked in Tremco’s Fire division for six years.

About Fire

With the recent Grenfell Tower fire in London in mind, Paul took the opportunity to tap into Mike’s store of expertise about addressing fire issues in the building process.

Mike noted that building codes evolve in response to such disasters and referred to the MGM Grand Hotel and Casino fire in 1980, which resulted in major reforms in regulations related to fire safety.

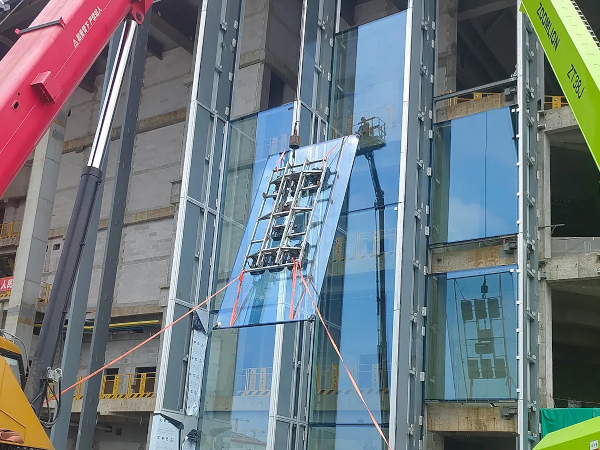

A major focus in regulations since the MGM fire is that fire and smoke should be prevented from moving vertically through the structure, for example, by way of vulnerabilities in the curtain wall.

Mike cites recent changes in the ASTM standards and the NFPA 285 standards for exterior cladding materials, such as air vapor barrier systems — changes that bring renewed attention to the flammability of the exterior skin.

That means testing the wall assembly — not just the new components — to study how fire interacts with the entire system. In fact, this approach aligns with Tremco’s single source solution to the entire building envelope.

Single Source Solution

Tremco supplies what Mike calls “a pretty big bandwidth of products” that covers all aspects of the building envelope, including below-grade waterproofing products and continuing up the wall to air barriers, glazing, deck coatings, and tying into the parapet or roof.

This gives Tremco a unique ability to develop and test whole systems, which helps alleviate the limitations of working with individual components.

Issues that could compromise the integrity of the building envelope — such as where one material in the building envelope transitions to another, penetrations of the envelope, or connections to adjacent systems or structures — can be solved in-house.

Enhanced design and installation control also allows Tremco to offer warranties over the whole system, a distinct advantage for projects that would otherwise need to deal with complicated warranty systems on a piecemeal basis.

Tremco Tests

Tremco’s in-house testing capability provides a distinct advantage in product development and installation, and is also a key element of the company’s ability to offer warranties.

Tremco has the capacity to run the full gamut of the ASTM prescribed test in its lab facilities, as well as test components and assemblies to identify problem areas and improve system performance.

Tremco offers design professionals and consultants technical assistance for design and selection of the appropriate system for a project, such as deciding on permeable or non-permeable system, sheet or fluid-applied, and where to locate an air vapor barrier. The assistance may include assembling mock-ups of a system for testing.

Though there might be costs incurred for materials, there’s no fee for these services, which can be organized through a Tremco representative.

Substrate Frontiers

Technical specialists at Tremco are currently preoccupied with changes in concrete admixtures that may affect their products. Another concern is restorations, where concrete is often left in a fractured condition, creating the potential for unpredictable conditions.

Testing methods are being developed that will allow Tremco to evaluate the substrate and the conditions that could impact on waterproofing products, enabling informed recommendations.

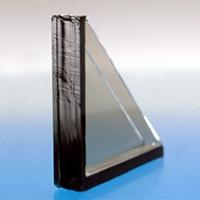

You can hear more of this comprehensive discussion — including an overview of extruded seals for glazing and an enlightening comparison of fluid-applied waterproofing with the sheet-applied system — at the “Everything Building Envelope” website.

While you’re there, take a moment to subscribe so that you don’t miss any of the expertise and insight that industry professionals share in conversation with Paul Beers.

600450

600450

Add new comment