Date: 26 August 2008

A new high definition, full colour touch-screen monitor makes understanding and operating the line a simple task. Mimics and Windows-style screen layouts mean anyone using computers will find the menus familiar and comfortable to use.

Various operating modes are included as standard, for example: processing of over-length units in a dual pressing cycle. Or assembling Triple rather than Double glazing units. Different operating modes on the final tilt section allow energy costs and wear-and-tear to be minimised when small units are being processed.

On a recent installation for Sunshine Performance Glass, in Florida USA, a new mode was written into the program. SPG makes units that call for the inner glass pane to be a different thickness from the outer one. The new mod allows them to pre-enter two thicknesses. Ashton’s VWPRO washer automatically sets the washing brushes to their ideal setting, alternating between the two sizes each time a pane enters.

Processing of stepped units, in one or both axes, is optional, as is laser marking of company logos, production dates, EN/BS numbers and even piece-specific information. There is a built-in Ethernet link to Ashton Industrial's software support service.

Free telephone and online support are offered- for life!

Interfacing to all proprietary brands of sealing robot is possible, and designs of all off-line machines including rotary sealing tables, desiccant fillers, tube saws and benders have all been overhauled and optimised for maximum reliability and operator comfort.

Ashton Industrial’s Butyl Extruder is still top value compared to other proprietary brands. Proven in arduous real production conditions for more than 10 years now.

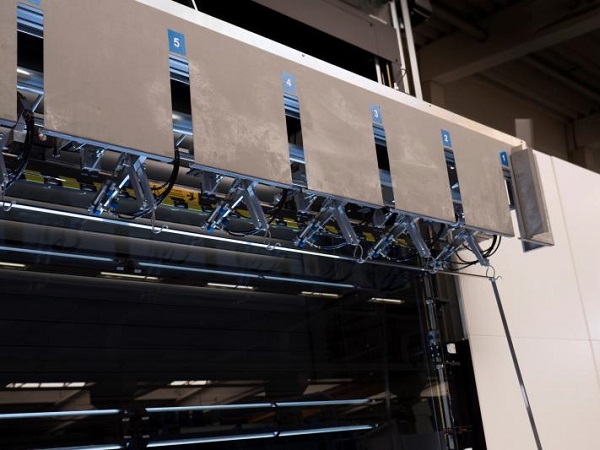

Conveyors near the wet zone have had a face lift, a new all-aluminium rust-free construction adds a nice finishing touch.

This year, Ashton Industrial celebrates 25 successful years in business. For more than 20 of those, IG lines have featured as a major product line, with installations in the UK and mainland Europe, the USA, Russia, and the Middle East.

Former Bystronic sales consultant Ross Worral has joined the Ashton team and is actively promoting the new upgraded IGPRO lines in the UK and Ireland.

Prices are keen, new Lean Manufacturing techniques are being implemented continuously, steered by new Production Manager and former MAS Manufacturing Advisory Service consultant, Stewart Barrass.

Add new comment