Date: 11 December 2014

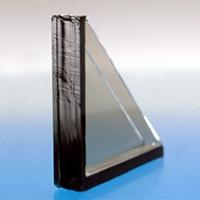

The BF website www.bundesverband-flachglas.de/shop/kostenfreie-downloads/bf-data-sheets-english lists test reports in two categories. At the top of the page are results for spacer bars suitable for simulation with Polyurethane (PU), Polysulphide (PS) and hot melt sealants. These spacer bars have been proven to pass EN1279 parts 2 and 3 with all secondary sealant types. At the bottom of the page is a list of spacer bars that have only been tested with hot melt sealant and can therefore only be simulated with this type of sealant. As stated by the British Fenestration Rating Council (BFRC) in recent publicity, “the BFRC will only accept simulation reports that have a listed combination of spacer bar and sealant.” Thermobar with hot melt sealant currently offers the best 2-box value available. Thermoseal Group’s Sales Director Mark Hickox, comments: “We have spoken to a few customers who are under the misconception that the BF data sheets listed at the bottom of the BF web page in the section ‘Data sheets only valid for use with hotmelt-sealant:’ are the only ones suitable for use with hot melt. This is incorrect. These data sheets are those which can be used with hot melt but have not demonstrated suitability for use with PU and PS data sheets. All of the data sheets listed above this section can be used with all sealant types. We are pleased to say that Thermobar is not only suitable for use with PS and PU, it also offers the best 2-box model value available with hot melt!” To download the latest BF data sheet, visit www.bundesverband-flachglas.de. The link to our data sheet is: http://www.bundesverband-flachglas.de/cms/upload/datenblaetter_engl/BF_Datasheet_27_Thermobar.pdf To find out about Thermoseal Group and its comprehensive range of insulated glass components and machinery for glazing manufacture, call +44(0)121 331 3950 or visit www.thermosealgroup.com.Thermobar Warm Edge Spacer, manufactured by Thermoseal Group, is officially at the top of the list of the most thermally efficient spacer systems suitable for use with both PU/PS and hot melt sealants as per figures published on the new Bundesverband Flachglas (BF) Data Sheet – 0.14W/mK.

The BF website www.bundesverband-flachglas.de/shop/kostenfreie-downloads/bf-data-sheets-english lists test reports in two categories. At the top of the page are results for spacer bars suitable for simulation with Polyurethane (PU), Polysulphide (PS) and hot melt sealants. These spacer bars have been proven to pass EN1279 parts 2 and 3 with all secondary sealant types. .jpg) At the bottom of the page is a list of spacer bars that have only been tested with hot melt sealant and can therefore only be simulated with this type of sealant. As stated by the British Fenestration Rating Council (BFRC) in recent publicity, “the BFRC will only accept simulation reports that have a listed combination of spacer bar and sealant.” Thermobar with hot melt sealant currently offers the best 2-box value available.

At the bottom of the page is a list of spacer bars that have only been tested with hot melt sealant and can therefore only be simulated with this type of sealant. As stated by the British Fenestration Rating Council (BFRC) in recent publicity, “the BFRC will only accept simulation reports that have a listed combination of spacer bar and sealant.” Thermobar with hot melt sealant currently offers the best 2-box value available.

Thermoseal Group’s Sales Director Mark Hickox, comments: “We have spoken to a few customers who are under the misconception that the BF data sheets listed at the bottom of the BF web page in the section ‘Data sheets only valid for use with hotmelt-sealant:’ are the only ones suitable for use with hot melt. This is incorrect. These data sheets are those which can be used with hot melt but have not demonstrated suitability for use with PU and PS data sheets. All of the data sheets listed above this section can be used with all sealant types. We are pleased to say that Thermobar is not only suitable for use with PS and PU, it also offers the best 2-box model value available with hot melt!”

To download the latest BF data sheet, visit www.bundesverband-flachglas.de. The link to our data sheet is: http://www.bundesverband-flachglas.de/cms/upload/datenblaetter_engl/BF_Datasheet_27_Thermobar.pdf

To find out about Thermoseal Group and its comprehensive range of insulated glass components and machinery for glazing manufacture, call +44(0)121 331 3950 or visit www.thermosealgroup.com.

Add new comment