Date: 27 March 2017

Comfortable, fast, clean, and bright. Today high-speed rail has become the number one choice for many travelers. Currently, the high-speed trains in China run at a speed of 200 to 300 kmh.

People who have the experience of looking out the train window often question why the scenery outside is still able to remain clear without causing dizziness at such a high speed and how the windscreen can safeguard passengers in an event of bird collision.

They may also wonder what type of glass a high-tech train uses and how the glass is manufactured. Below, we will answer these questions one by one.

Generally, we may see distorted image when looking through glass due to optical distortion which affects all glass to some extent.

Moreover, for an object moving at a high speed, the stacking velocity may easily make you dazzled and lead to dizziness.

To prevent this, the side window glass used by the Chinese high-speed rail system has minimized the permissible error in terms of thickness and flatness of the glass by homogenizing glass materials.

When the uniformity of the refractive index is warranted, the image we see will be the same as it is. The glassless visual effect effectively eliminates the dizziness. Thus, travelers will feel more relaxed to enjoy the journey.

In addition to the excellent visual effect, one important feature of the high-speed rail side window glass is its safety.

The air pressure wave created by high speed trains moving in opposite directions will cause tremendous impact against the side window, a force large enough to possibly break the glass and result in safety concern to both passengers and the train operation.

Therefore, the side window must have sufficient mechanical strength and resistance against such impact. In the event where the window does break under force, it is required that glass shatters into honeycomb shaped tiny granular chunks with no sharp edges.

The outer layer should peel off free of debris while the inner layer remains intact, providing better protection to passengers against injuries for a safe trip.

Let’s now take you to a journey of discovery to find out how the window glass for high-speed rail achieves these superior performance requirements.

Let’s now take you to a journey of discovery to find out how the window glass for high-speed rail achieves these superior performance requirements.

Currently, among companies that offer side window glass for high-speed rail, Jiangsu Tiemao Glass Co., Ltd., Qingdao Jinjing Co.,Ltd., Shanghai Yaohua Pilkington Glass Group Co. Ltd., and Jilin Liyuan Precision Manufacturing Co., Ltd. are the major manufacturers of the safety glass for high-speed rail system, accounted for 90% of the market share in this specialized glass application field.

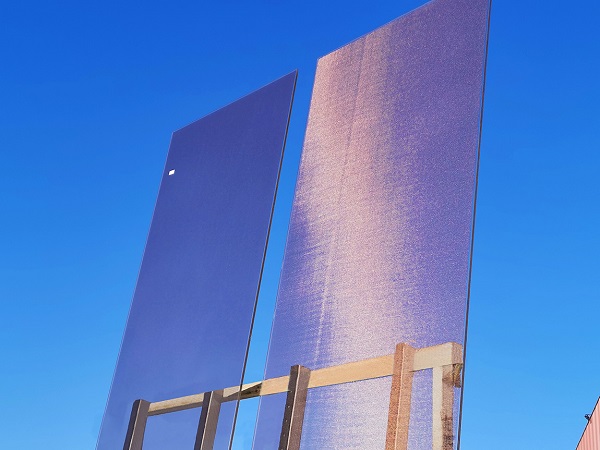

The high-performance of high-speed railway glass is backed up by state-of-the-art technology. When you walk into the factories of these enterprises, you will find that every one of them is equipped with the glass tempering furnaces made by LandGlass.

LandGlass glass tempering furnace adopts the world’s leading JetConvection heating approach, injecting high temperature heated air streams vertically to both upper and lower surface through convection blowers, convection heating chamber, and air circulating convection system. There, pieces of glass sheets are quickly and evenly heated to 600~700oC.

One of the decisive steps to ensure the high quality of the tempered glass is that any spot on both sides of the glass must receive even heating during this process. The glass then undergoes a cooling procedure called quenching.

The equipment powered by LandGlass’ unique cooling system and tempering technology will intelligently adjust the air pressure and duration of the blowing based on the needs of the glass for a desired effect.

Eventually, an ordinary piece of glass has now become the tempered glass with least waviness, high degree of flatness, excellent optical properties, even stress, and strength many times better than its original version.

It also means that a piece of regular glass has now been upgraded to safety glass with great visual effect, free of distortion, and high impact resistance. All of these are achieved through this magic glass tempering machine made by LandGlass.

After being tempered, it has to further undergo other corresponding procedures such as laminating and insulation before it can be used as high speed rail side window glass as we see today.

In the future, while the list of China’s high speed railway projects keeps growing, including more and more worldwide customers, our high speed rail window glass and its processing enterprises will bring another domestic brand labeled “Made in China” to the world.

600450

600450

Add new comment