Latest articles

| After seaming, grinding glass edges is another important work step in glass edge processing. The process is primarily used to remove overbreaks and underbreaks at the edges and to process the glass sheets to size.

| In glass edge processing, cutting the glass sheet is directly followed by the seaming process. Fully unprocessed glass edges exhibit overbreaks and underbreaks, conchoidal fractures, as well as micro-cracks along the broken edge.

| The paper illustrates the design project of the main laminated glass balustrade of a steel staircase installed in the historical Margherita Theatre in Livorno, Italy.

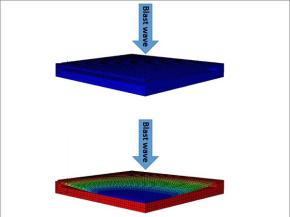

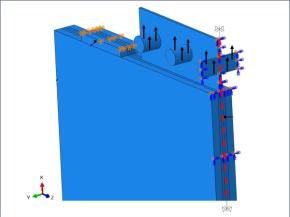

| In this paper, the emphasis is put on explosion resistant glazing systems.

| In glass edge processing, the requirements for the finished components can vary greatly depending on the location and purpose.

| In glass tempering, we look for equipment that uses less energy, leading to fewer emissions. But sometimes, the numbers are too good to be true.

| Making new and existing buildings as energy efficient as possible is one way to help meet the EU’s CO2 reduction goals.

| The significance of balancing operational and embodied carbon continues to grow.

| Global environmental concern is motivating efforts to improve energy efficiency in all industrial sectors. And glass tempering is no exception.

| There are parts of the window inside the glass that play a crucial role in its performance.

| Today, almost all new devices – from home appliances to production equipment – are connected. Rapid development in consumer electronics has been increasingly moving towards industrial use. In the glass industry, this development is still in its…

| Interview with Émilie Develle, technical advisor, Guardian Glass Europe.

| To really succeed in glass lamination, it takes much more than just having the best equipment – it’s about understanding the process in and out.

| The aim of this paper is to explain how the design intent of a bespoke glazed façade develops from the point of view of the façade consultant BIFF SA.

| The two case studies illustrate how the engineering of glass can fluctuate with design intent in unusual scenarios – when we cannot rely solely on conventional codes and standards to guide the analysis.

| When people talk about the future of production, they can't do so without using the term "smart factory." But what is it? How does a smart factory work? And what does it have to do with OPC UA?

| Five commercial glazing system analysis and a project study show the advantages of using Insulated Glass Unit (IGU) edges to mechanically attach glass to buildings.

| Analysis of worldwide glass industry developments and trends.

| Glass production is an energy-intensive process by its nature, so even small reductions there can result in considerable savings in energy and costs.

| High strength load-bearing connections between glass components are challenging because they are required to transmit high forces in a material that is sensitive to stress concentrations.