Fatemeh Pariafsai

Young Researchers and Elite Club, Yadegar-e-Imam Khomeini (RAH) Branch, Islamic Azad University, Tehran, Iran

pariafsai@hotmail.com

Abstract

When the visual presence of materials decreases, the maximal transparency creates astounding beauty. In order to enhance transparency, clearer and lighter structures should be used. Although glass is extremely noteworthy as a transparent load bearing material, the structural use of glass is still unfamiliar to architects.

Since the advancement in architecture requires knowledge about the path of developments, this study was conducted in order to discern the potential of improvement in glass structures as a result of scientific and technological advances. Through analysis of existing challenges and opportunities, this study aims to investigate the possibility of constructing completely transparent buildings in the near future.

The findings indicate that improvements in the field of materials, selection of appropriate forms, the advent of innovative techniques, plus fine-tuning the existing technologies can improve structural efficiency, safety, durability, and transparency of glass buildings, so that the imagination of modern architecture can be realized.

1. INTRODUCTION

Glass has been used in construction since approximately 2000 years ago [1, 2]. Recently, the use of this environmentally friendly material has been developing in construction due to the following reasons:

- Very high compressive strength [3, 4]

- Resistance to corrosion [3, 5]

- Being recyclable [6, 7]

- Reducing energy consumption [7, 8]

- Recent advances in glass coatings [8, 9]

- the development of computers and programs [10]

- The growing demand in architecture for thinner and more transparent structures [4, 9]

However, one of the challenges is how to exploit the maximum potential of glass to achieve the maximum transparency.

In order to modify the structural behavior of transparent buildings, all opportunities should be carefully identified. For this purpose, this study analyzes the opportunities presented by recent advances in order to determine how each novel approach can affect the future of transparent buildings.

This study determines how scientific and technological progress can expand the application of glass in construction and how innovative solutions can provide the opportunity for creating completely transparent buildings.

2. THE ADVENT OF MORE EFFICIENT MATERIALS

2-1. PRE-STRESSED GLASS

Structural behavior of glass can be improved by pre-stressing and lamination. Pre-stressed types of glass have considerably higher tensile strength [11, 12], thus adding new dimensions to the design of glass structures.

Although stronger types have higher initial strength, their post-breakage strength is lower [13]. Furthermore, pre-stressed glass may stand up to impact damage, but it does not warn of overloading whereas an ordinary annealed glass is less sensitive to local impacts, and the damaged area will be limited on it [14]. However, annealed glass is sensitive to thermal shocks, while both heat-strengthened and tempered glass, which are two pre-stressed types, are less susceptible to the changes in temperature [15].

Moreover, the longer the duration of loading, the lower the failure stress is expected [16, 17]. This phenomenon is called static fatigue [17]. On the other hand, the maximum load below which glass would be free of static fatigue is unknown [18]. Static fatigue is very sensitive to atmospheric factors and cab be accelerated by temperature and humidity [18].

Thermally tempered glass is more resistant to static fatigue [18] because its long term strength is higher [19]. However, it breaks into many small fragments [3, 20, 21], so that it has almost no residual strength [21]. In contrast to tempered glass, both annealed and heat-strengthened glass produce relatively large glass shards at breakage [22] (Figure 1). The larger glass fragments help the laminate achieve higher post-breakage strength [23].

![Figure 1. Typical crack pattern of heat-strengthened glass (left) [24] and tempered glass (right) [25]](/sites/default/files/inline-images/Fig1_156.jpg)

2-2 HYBRID LAMINATES

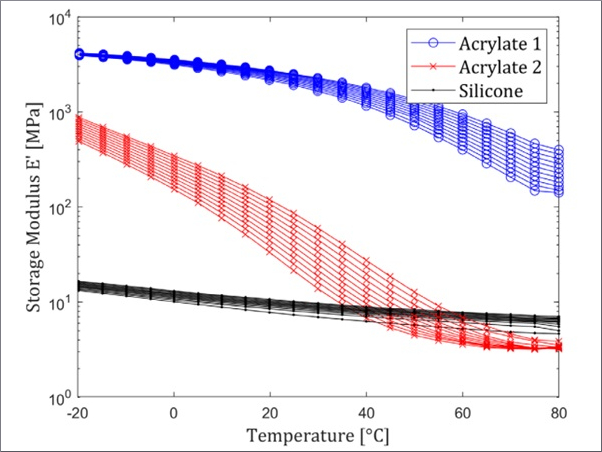

After breakage, glass components must remain in place and support loads [22]. In case of breakage, the broken pieces of laminated glass remain bonded to the interlayer [26], so that broken glass can be left in place until replacement [3]. Therefore, for structural applications, laminated glass is used in order to improve the post-failure behavior [27, 28]. The required thickness of laminate depends on the duration of load plus temperature [15]. The properties of laminate clearly diminish with increasing loading duration and temperature [3, 27].

Furthermore, hybrid laminates offer excellent performance both before and after breakage [29]. Combining tempered and non-tempered plies provides acceptable strength, impact resistance and post-breakage integrity economically [29]. In addition, the use of hybrid laminates significantly reduces dead loads [30]. In other words, hybrid laminates take advantage of the positive characteristics of various glass types and minimize their undesirable aspects [29]. On the hand, the damping ratio of composites is higher than that of pure glass sheets [31]. Therefore, laminates improve the dynamic behavior of glass structures too.

2-3. SENTRYGLAS® PLUS (SG) INTERLAYER

The SG structural interlayer has considerably enhanced the performance of laminated glass both before and after breakage [32, 33] since it is significantly stiffer, tougher and chemically more robust than traditional interlayers [34]. In addition, Sentry glass plus improves the appearance of laminate because it doesn‟t have the yellow tint that can be found in many other interlayers [35].

On the other hand, the SG interlayer completely couples glass plies in the laminate which results in stronger, less deflected, thinner, larger laminated panels [32]. Moreover, the idea of laminating metal within the body of laminated glass has been possible by the SG interlayer (Figure 2) due to its superior flow characteristics [33].

![Figure 2. Lamination of metal within the body of laminated glass resulted in thinner joints (top) [36] (bottom) [37]](/sites/default/files/inline-images/Fig2_159.jpg)

2-4. TRANSPARENT INTUMESCENT COATINGS

The poor fire resistance of ordinary glass limits its use as a structural material [38]. Unlike ordinary glass, borosilicate glass is fire-resistant [38-40], but it isn‟t commonly used in construction [38]. Annealed glass is an unsafe structural material on exposure to fire whereas tempered glass is more resistant, so that small fires pose no danger to structural elements made of tempered glass [38].

However, long duration and high temperature fires reduce the pre-stress level of tempered glass, thus making it necessary to completely replace structural elements after exposure to fire [38]. In addition, discontinuous laminates are also sensitive to fire. Since fire de-bonds the glass segments locally, the structure buckles quickly. However, adding an outer layer, which forms an insulating cavity, can reduce the risk of buckling [38].

On the other hand, transparent fire-protective materials can improve the performance of glass structures on exposure to fire. For instance, transparent intumescent coatings reduce thermal exchanges by slowing down the development of thermal strain in glass elements. Furthermore, using intumescent paints on structural glass elements eliminates the need for replacing structural elements after small fires [38]. Additionally, heat turns an intumescent interlayer into opaque insulating foam which slows down the development of thermal strain [39]. However, it is not clear how aging affects the fire resistance of an intumescent material [39].

3. SELECTION OF APPROPRIATE FORMS

3-1. CURVED SHELLS

Glass can be bent through either elastic strain (cold-bending) or plastic deformation (warm bending) [41]. Nowadays, curved shapes with radii of 40m can be produced [42]. However, bent glass is more expensive than flat glass [43].

Single and double curved shells are among the best configurations for glass structures since they can carry symmetric loads via compressive forces [19]. In general, curved structures are much more efficient than flat structures because they can carry loads via membrane forces [19]. In other words, the stiffness-to-weight ratio of a curved structure is higher because it absorbs loads by its overall shape instead of a local sectional area [44, 45]. On the other hand, the global geometry minimizes long term bending moments in laminated glass, thus avoiding weakening effects caused by creeping of the interlayer [19].

Moreover, adhesive joining has made it possible to build self-bearing glass shells without any metal frame or connection [30] (Figure 3). In addition to transmitting loads, the adhesive technology allows for adjusting tolerances [30]. Furthermore, joining the panes along the edges not only minimizes stress concentrations, but also brings about continuous surfaces without any optically disturbing element [46].

![Figure 3. A completely transparent shell structure [47]](/sites/default/files/inline-images/Fig3_145.jpg)

On the other hand, the use of corrugated glass as facades is advantageous [42] since folding enlarges the lever of both pressure and tension areas in the material dramatically [48], so that corrugated panels stand firmly and take up much more wind load than flat ones with the same thickness. In other words, they are more resistant to both buckling and plying [48].

Additionally, corrugated panels carry permanent loads mostly by diaphragm action whereas they support short term loads by shell action, thus avoiding undesirable creep effects caused by high stresses in the laminates and joints over the years [42]. Corrugated glass can also be used as load carrying walls (Figure 4), although its use is limited by the size of panels which cannot be fabricated larger than 6 m in length [49].

![Figure 4. Corrugated panels as facades [25]](/sites/default/files/inline-images/Fig4_144.jpg)

3-2. FACETTED SHELLS

On the one hand, facetted shell structures take advantage of double curved shapes. On the other hand, they are made of flat elements, thus reducing the cost of production [43, 45]. When all vertices have three adjoining facets, the facetted shell carries load via in-plane stresses in the facets, and shear distributed along the edges [43, 45, 50] (Figure 5). Since stress concentrations are avoided, glass is an appropriate load carrying material for these structures [45].

However, forces in the connections of facetted shells are different from those of smooth domes [44]. The connections of a smooth dome transfer loads primarily via in-plane forces, thereby leading to relatively low stresses [51] whereas facets of a facetted shell locally bend under distributed loads, thus leading to higher stresses in the connections [44].

![Figure 5. Glass dome with three-way vertices and glued joints [45]](/sites/default/files/inline-images/Fig5_145.jpg)

3-3. Borosilicate glass tubes

Structural use of glass tubes provides new design possibilities for architecture [52]. Because of its resistance to both torsion and buckling, a tube is the best shape for a transparent column [53]. Moreover, the risk of delamination is lower in a tubular laminate column because the exposed length of its interlayer is shorter. On the other hand, welding does not have any negative impact on the strength of welded tubes (Figure 6), so that butt-welded glass tubes can be used as structural elements [54].

![Figure 6. Butt-welded glass tubes for structural applications [52]](/sites/default/files/inline-images/Fig6_119.jpg)

In pure compression, transparent columns, which are consisted of two borosilicate glass tubes laminated with a clear resin, exhibit gradual and safe failure behavior since the damaged glass tubes can still carry loads until the complete cross-section at a particular height delaminates [53].

However, these columns pose their own specific problems [52]. For instance, connecting glass tubes to an external structure is tricky [55]. Furthermore, little difference in length between inner and outer tubes, distortions at the ends of the tubes, or inappropriate support conditions can cause local stresses in these columns [53].

4. THE ADVENT OF MODERN TECHNIQUES

4-1. FINITE ELEMENT ANALYSIS APPROACH

In order to design with glass, its local behavior under loads must be predicted. This prediction has been made possible through the finite element analysis approach. Furthermore, the advancements in computer science has facilitated the analysis, so that the local behavior of glass under loads can be predicted more accurately and more quickly [10]. For example, the structural behavior of laminates varies between mid-sections and close to supports.

Near the supports, the composite behavior is close to the layered limit, so that the laminates can‟t be considered monolithic elements [56]. Since a well-composed finite element analysis clarifies the unknown aspects of laminates in complex situations [27], more dependable glass structures can be designed (Figure 7).

![Figure 7. Glass structure (left) [57] and glass load-bearing walls (right) [58]](/sites/default/files/inline-images/Fig7_111.jpg)

4-2. ALTERNATIVE LOAD PATHS AND SACRIFICIAL SHEETS

The safety of glass structures can be boosted by incorporating alternative load paths or sacrificial sheets in the design. For example, in the ATP (all transparent pavilion), the roof panels rest on more than one facade panel, so that the roof panels remain in place in case of complete failure of one facade panel [20] (Figure 8).

Furthermore, the rigid grid of beams and purlins can provide an alternative load path in the event of the complete collapse of a column [20]. On the other hand, sacrificial glass layers can protect the core panes of glass beams against accidental damage in order to increase the safety of glass structures [20, 59].

4-3. ELASTIC JOINTS AND LATERAL SUPPORTS

Since out-of-plane movement can limit the load-bearing capacity of glass elements, one of the main concerns when loading slender glass members in compression is buckling instability [60-62]. Elastic joints, which connect glass beams with superstructures, reduce the risk of buckling, thus increasing the overall load-bearing capacity of glass beams [60].

Further, lateral supports along the length of beams can prevent their out-of-plane movement [61]. For example, in ATP (figure 8), rigid connections between purlins and main beams prevent the main beams from tilting and creating hinges between the top side of beams and roof panels, thereby increasing both global and local stability of the structure [20].

![Figure 8. Model of the All Transparent Pavilion design [20]](/sites/default/files/inline-images/Fig8_88.jpg)

4-4. REINFORCED COMPOSITES

Glass is brittle and its tensile strength is small [63] and unreliable due to the random distribution of surface flaws [27] that induce cracks suddenly [64]. Therefore, the ductility of structural glass elements must be ensured.

In combination with other materials, which can absorb tensile stresses, glass can be used as an efficient structural material [64]. So far different techniques have been experienced to strengthen the laminate structural elements [65-67] in order to attain "pseudo-ductile" behavior [66].

For instance, glass elements can be reinforced by means of glass fiber rods [65, 68]. Such elements are made by alternating glass and sheets of GFRP (Glass Fiber Reinforced Polymers) [69, 70] or by coupling glass and glass fibers profiles [70]. These techniques prevent the fragile fracture of structural glass elements [70].

For instance, embedding reinforcement glass fibers in laminate beams is beneficial [68, 71]. On the one hand, the reinforcement rods, connected to glass by the interlayer, carry the tensile forces when glass breaks [68]. On the other hand, the reinforced glass beams are almost transparent because limited amount of glass fibers is sufficient for reinforcement [68]. Such beams can safely be used in structures as an appropriate alternative to metal reinforced glass beams [68].

4-5. CUTTING AND FINISHING

Careful cutting and finishing can increase the efficiency of glass structural elements [72]. For instance, polished glass edges guarantee adequate contact between glass segments. In compression zones, the contact between segments functions as a medium for transferring loads. Bad contact results in uneven load distribution, thereby inducing local stresses in glass [73]. In addition, finishing affects both number and shape of cracks, thus affecting the edge strength of glass which plays an important role in designing structural glass elements [72].

4-6. ADHESIVE JOINING TECHNOLOGY

Adhesive joining technology has added new dimensions to the design of glass structures [47, 74-76] . Efficient adhesive minimize the visual effect of joints [46, 47, 51, 74, 77], compensate for tolerances [30, 46, 78, 79], and dampen shock loads [79, 80]. Moreover, adhesive connections evenly distribute stress in glass due to relatively large contact areas, thus reducing stress concentrations in glass elements [77, 81].

In addition, just like glass, adhesives have higher strength in compression than in tension [46]. Therefore, adhesive joints are ideal for glass structures which carry loads primarily via compressive membrane stresses like glass shells of positive curvature [19].

5. CONCLUSIONS

The results of this study indicate that completely transparent buildings can be designed and constructed in the near future. Recent advancements in science and technology have increased transparency, structural efficiency, safety, and durability of glass buildings. Firstly, the use of more efficient materials in construction of glass structures improves the structural behavior, safety and appearance of transparent buildings. For instance:

- Pre-stressed glass has higher initial strength, although it shows less residual strength.

- The use of hybrid laminates allows designers to take maximum advantage of both tempered and non-tempered glass.

- Transparent intumescent coatings enhance the fire resistance of structural elements, thus obviating the need for their replacement after small short-term fires.

- By using the SG interlayer, which opened the opportunity to laminate metal within the body of the glass, the visual effect of joints can be reduced.

- The SG interlayer, which does not possess the yellow tint, enhances not only the clarity of the laminate, but also its strength, so that structural elements can be made thinner.

Secondly, appropriate forms bring about lighter, clearer, and more durable glass structures. For example:

- Curved glass, which are more expensive, exhibits better structural behavior than flat glass.

- Curved forms, which increase the stiffness-to-weight ratio, reduce the weight of glass structures.

- Glass tubes, corrugated panels, and curved shells make it possible to build more durable structural elements since they either shorten the exposed length of the interlayer or reduce long-term bending moments in glass elements.

- Facetted shell structures, which take considerable advantage of double curved shapes, reduce the cost because flat glass elements are used for their construction.

- Suitable forms allow using adhesive or welding technology for joining structural glass elements, thus increasing transparency.

Thirdly, technological advancements plus innovative techniques have improved the possibility of both design and construction of completely transparent structures. For instance:

- The finite element analysis approach has increased both reliability and speed of design since the behavior of glass under loads can be predicted more precisely and more quickly through finite element.

- Alternative load paths, sacrificial glass layers, appropriate joints and supports can increase safety, strength, and stiffness of glass structures.

- Reinforcement with glass fiber rods and pre-tension can significantly increase the residual strength of glass beams.

- Acceptable cutting and finishing can improve the quality of glass edges which is an important issue when designing structural elements.

- The adhesive technology made it possible to manufacture all transparent shell structures.

Completely transparent buildings create a seamless flow between interior and exterior, thereby expanding the vocabulary of architecture. The designers who keep abreast of the latest advances in science and technology have more chance to keep up with the new developments. On the other hand, assessing the effectiveness of both existing and innovative solutions can help them to optimize their designs.

In addition, a conceptual framework for in-depth research, which is needed for overcoming the remaining obstacles, can be provided since the limitations of each solution can also be discerned through the assessment. Lastly, the more the obstacles are removed, the more glass can be used in construction so that, less can become more than before.

6. REFERENCES

1.Knaack, U.: „Driving the future of glass‟, in Editor (Ed.)^(Eds.): „Book Driving the future of glass‟ (IOS Press, 2008, edn.), pp. 571-578

2.Mocibob, D.: „Glass panel under shear loading - Use of glass envelopes in building stabilization‟. PhD Thesis, EPFL Ecole polytechnique federale de Lausanne 2008

3.Hess, R.: „Material glass‟, Structural engineering international, 2004, 14, (2), pp. 76-79

4.Luible, A., and Crisinel, M.: „Buckling design of glass elements under compression‟, in Editor (Ed.)^(Eds.): „Book Buckling design of glass elements under compression‟ (2004, edn.), pp. 1-12

5.Wilson, P., and Vasilchenko-Malishev, G.: „Construction of all-glass structures with external glass frames‟, in Editor (Ed.)^(Eds.): „Book Construction of all-glass structures with external glass frames‟ (2005, edn.), pp. 1-3

6.Nijsse, R.: „Glass in structures: elements, concepts, designs‟ (Birkhäuser, 2003, 1st edn. 2003)

7.Siebert, B.: „Application of glass as load-bearing element in structural engineering‟, in Editor (Ed.)^(Eds.): „Book Application of glass as load-bearing element in structural engineering‟ (International Association for Bridge and Structural Engineering, 2002, edn.), pp. 91-100

8.Tückmantel, P.: „The future of glass – examples of innovative products and forms‟, in Editor (Ed.)^(Eds.): „Book The future of glass – examples of innovative products and forms‟ (Glass Performance Days, 2009, edn.), pp. 152-159

9.Bostick, C.W.: „Architectural trends thru the looking glass‟, in Editor (Ed.)^(Eds.): „Book Architectural trends thru the looking glass‟ (Glass Performance Days, 2009, edn.), pp. 860-866

10.O'Callaghan, J., and O´Callaghan, E.: „Adventures with structural glass‟, in Editor (Ed.)^(Eds.): „Book Adventures with structural glass‟ (2012, edn.), pp. 2-6

11.Belis, J., Van Impe, R., and Piras, A.: „Effect of residual stresses on the buckling behaviour of glass beams‟, in Editor (Ed.)^(Eds.): „Book Effect of residual stresses on the buckling behaviour of glass beams‟ (2005, edn.), pp. 537-539

12.Pankhardt, K., and Balázs, G.L.: „New opportunities of structural glazing, loadbearing glass structures‟, in Editor (Ed.)^(Eds.): „Book New opportunities of structural glazing, loadbearing glass structures‟ (International Association for Bridge and Structural Engineering, 2006, edn.), pp. 15-25

13.Louter, C., Belis, J., Veer, F., and Lebet, J.-P.: „Structural response of SG-laminated reinforced glass beams; experimental investigations on the effects of glass type, reinforcement percentage and beam size‟, Engineering Structures, 2012, 36, (0), pp. 292-301

14.Louter, P.C., Belis, J., Bos, F.P., Veer, F.A., and Hobbelman, G.J.: „Reinforced glass cantilever beams‟, in Editor (Ed.)^(Eds.): „Book Reinforced glass cantilever beams‟ (2005, edn.), pp. 429-433

15.Wilson, P., and Vasilchenko-Malishev, G.: „The design and construction of all glass structures‟, in Editor (Ed.)^(Eds.): „Book The design and construction of all glass structures‟ (IASS: the International Association of Shell and Spatial Structures, 2006, edn.), pp.

16.Dodd, G.: „Structural glass walls, floors and roofs‟, Structural engineering international, 2004, 14, (2), pp. 88-91

17.Wai So, A.K., and Chan, S.L.: „Stability and strength analysis of glass wall systems stiffened by glass fins‟, Finite Elements in Analysis and Design, 1996, 23, (1), pp. 57-75

18.Gy, R.: „Creep and recovery of a thermally tempered glass plate at room temperature‟, in Editor (Ed.)^(Eds.): „Book Creep and recovery of a thermally tempered glass plate at room temperature‟ (1999, edn.), pp. 63-66

19.Weber, F.: „Curved glass structures‟, in Editor (Ed.)^(Eds.): „Book Curved glass structures‟ (Glass Performance Days, 2009, edn.), pp. 375-380

20.Bos, F., Veer, F., Hobbelman, G., Romein, T., Nijsse, R., Belisx, J., and Louter, C.: „Designing and Planning the World‟s Biggest Experimental Glass Structure‟, in Editor (Ed.)^(Eds.): „Book Designing and Planning the World‟s Biggest Experimental Glass Structure‟ (2005, edn.), pp. 401-405

21.Feirabend, S., and Sobek, W.: „Improved post-breakage behavior of laminated glass due to embedded reinforcement‟, in Editor (Ed.)^(Eds.): „Book Improved post-breakage behavior of laminated glass due to embedded reinforcement‟ (2009, edn.), pp. 726-729

22.Yang, J., Bao, Y., Bao, M., and Han, E.: „Post-breakage strength of glass used as a structural material‟, in Editor (Ed.)^(Eds.): „Book Post-breakage strength of glass used as a structural material‟ (2012, edn.), pp. 185-193

23.Feirabend, S.: „Reinforced laminated glass‟, in Editor (Ed.)^(Eds.): „Book Reinforced laminated glass‟ (IOS Press, 2008, edn.), pp. 469-477

24.http://1stchoicewindowsandshutters.com/ basics-annealed-heat-strengthened-tempered-glass/, accessed July 7th 2015

25.http://construction.com/CE/CE_images/ 2010/May_AR_2.jpg

26.Delincé, D., Callewaert, D., Belis, J., and Van Impe, R.: „Post-breakage behaviour of laminated glass in structural applications‟, in Editor (Ed.)^(Eds.): „Book Post-breakage behaviour of laminated glass in structural applications‟ (IOS Press, 2008, edn.), pp. 459-467

27.Callewaert, D., Delincé, D., Belis, J., and Van Impe, R.: „Stiffness of laminated glass: influence of different loading conditions‟, in Editor (Ed.)^(Eds.): „Book Stiffness of laminated glass: influence of different loading conditions‟ (Glass Performance Days, 2009, edn.), pp. 730-733

28.Henriksen, T.: „Future Application of Structural Use of Glass‟, in Editor (Ed.)^(Eds.): „Book Future Application of Structural Use of Glass‟ (IOS Press, 2012, edn.), pp. 67-70

29.Chaszar, A.: „Hybrid laminations for structural glass‟, in Editor (Ed.)^(Eds.): „Book Hybrid laminations for structural glass‟ (2003, edn.), pp. 416-418

30.Blandini, L.: „The glass dome‟, in Editor (Ed.)^(Eds.): „Book The glass dome‟ (2005, edn.), pp. 1-4

31.Lenk, P., and Coult, G.: „Damping of glass structures and components‟, in Editor (Ed.)^(Eds.): „Book Damping of glass structures and components‟ (TU Delft, 2010, edn.), pp. 341-350

32.Bennison, S.J., Davies, P.S., Gao, W., Zhu, F.F., and Amos, T.: „Glazing solutions with laminated glass beyond the PVB limit: the use of a structural interlayer‟, in Editor (Ed.)^(Eds.): „Book Glazing solutions with laminated glass beyond the PVB limit: the use of a structural interlayer‟ (2006, edn.), pp. 224-226

33.O‟Callaghan, J., and Coult, G.: „An all glass cube in New York City‟, in Editor (Ed.)^(Eds.): „Book An all glass cube in New York City‟ (2007, edn.), pp. 15-18

34.Bennison, S.J., Smith, C.A., Van Duser, A., and Jagota, A.: „Structural performance of laminated glass made with a “stiff” interlayer ‟, in Editor (Ed.)^(Eds.): „Book Structural performance of laminated glass made with a “stiff” interlayer ‟ (ASTM International, 2002, 1st edn.), pp. 57-65

35.O‟Callaghan, J.: „Apple computer Inc retail store - All glass staircase and bridge - A technical review of innovative design and fabrication techniques utilised‟, in Editor (Ed.)^(Eds.): „Book Apple computer Inc retail store - All glass staircase and bridge - A technical review of innovative design and fabrication techniques utilised‟ (2003, edn.), pp. 191-194

36.http://home.iitk.ac.in/~umraos/applestore.html

37.http://www.building.co.uk/glass-staircases-in- apple%E2%80%99s-covent-garden-store/5004618.article, accessed 27 August 2010

38.Veer, F.A., Voorden, M.v.d., Rijgersberg, H., and Zuidema, J.: „Using transparent intumescent coatings to increase the fire resistance of glass and glass laminates‟, in Editor (Ed.)^(Eds.): „Book Using transparent intumescent coatings to increase the fire resistance of glass and glass laminates‟ (2001, edn.), pp. 392-396

39.Boström, L.: „Ageing effects on the fire resistance of building structures: Brandforsk project 322-011‟ (Sveriges provnings-och forskningsinstitut (SP), 2002. 2002)

40.Leitch, K.K.: „Structure glass technology: systems and applications‟. M. Eng. Thesis, Massachusetts Institute of Technology, 2005

41.Chinzi, G.: „Curved glass surfaces: design, process definition & performances‟, in Editor (Ed.)^(Eds.): „Book Curved glass surfaces: design, process definition & performances‟ (Glass Performance Days, 2013, edn.), pp. 336-334

42.Fildhuth, T., and Knippers, J.: „Double curved glass shells from cold bent glass laminates‟, in Editor (Ed.)^(Eds.): „Book Double curved glass shells from cold bent glass laminates‟ (2011, edn.), pp. 384-389

43.Aanhaanen, J.A.M., Bagger, A., and Vamberský, J.N.J.A.: „The stability of a facetted glass dome structure‟, in Editor (Ed.)^(Eds.): „Book The stability of a facetted glass dome structure‟ (International association for shell and spatial structures 2008, edn.), pp. 1-9

44.Bagger, A.: „Plate shell structures of glass Studies leading to guidelines for structural design‟. Ph.D. Thesis, Technical University of Denmark, 2010

45.Bagger, A., Jönsson, J., Almegaard, H., and Wester, T.: „Facetted shell structure of glass‟, in Editor (Ed.)^(Eds.): „Book Facetted shell structure of glass‟ (2007, edn.), pp. 111-114

46.Blandini, L.: „Structural use of adhesives in glass shells‟, in Editor (Ed.)^(Eds.): „Book Structural use of adhesives in glass shells‟ (2003, edn.), pp. 183-185

47.Blandini, L., and Arch, M.: „Structural use of adhesives in glass shells‟, in Editor (Ed.)^(Eds.): „Book Structural use of adhesives in glass shells‟ (IOS Press, 2008, edn.), pp. 185-192

48.Nijsse, R.: „Corrugated glass as improvement to the structural resistance of glass‟, in Editor (Ed.)^(Eds.): „Book Corrugated glass as improvement to the structural resistance of glass‟ (Glass Performance Days, 2009, edn.), pp. 468-472

49.Nijsse, R.: „Corrugated glass as improvement to the structural resistance of glass‟, in Editor (Ed.)^(Eds.): „Book Corrugated glass as improvement to the structural resistance of glass‟ (IOS Press, 2008, edn.), pp. 399-412

50.Bagger, A., Jönsson, J., and Wester, T.: „Investigation of stresses in facetted glass shell structures‟, in Editor (Ed.)^(Eds.): „Book Investigation of stresses in facetted glass shell structures‟ (International Association for Shell and Spatial Structures, 2007, edn.), pp.

51.Blandini, L.: „Structural use of adhesives in glass shells‟. PhD thesis, Universität Stuttgart, 2005

52.Bos, F., Giezen, C., and Veer, F.: „Opportunities for the welding and hot-shaping of borosilicate glass tubes in building structural applications‟, in Editor (Ed.)^(Eds.): „Book Opportunities for the welding and hot-shaping of borosilicate glass tubes in building structural applications‟ (IOS Press, 2008, edn.), pp. 193-204

53.van Nieuwenhuijzen, E.J., Bos, F.P., and Veer, F.A.: „The laminated glass column‟, in Editor (Ed.)^(Eds.): „Book The laminated glass column‟ (2005, edn.), pp. 1-4

54.Bos, F., and Veer, F.: „Bending and buckling strength of butt-welded borosilicate glass tubes‟, in Editor (Ed.)^(Eds.): „Book Bending and buckling strength of butt-welded borosilicate glass tubes‟ (2007, edn.), pp.

55.Bos, F.P.: „Glass-to-acrylic and acrylic-to-acrylic cylindrical adhesive bonds‟, in Editor (Ed.)^(Eds.): „Book Glass-to-acrylic and acrylic-to-acrylic cylindrical adhesive bonds‟ (ISAAG, 2006, edn.), pp. 207-214

56.Gräf, H., Albrecht, G., Sackmann, V., Schuler, C., and Bucak, Ö.: „Structural behaviour of point-supported and clamped laminated glass‟, Structural engineering international, 2004, 14, (2), pp. 129-133

57.http://www.mimoa.eu/projects/United%20States /New%20York/Apple%20Store%20Fifth%20Avenue /?abvar4&utm_expid=3171585-1.pFu_x39wQKuggy22EudlKA.4 &utm_referrer=https%3A%2F%2Fwww.google.com

58.DuBois, M.: „Glass bearing walls - a case study‟, in Editor (Ed.)^(Eds.): „Book Glass bearing walls - a case study‟ (2007, edn.), pp. 179-183

59.Palumbo, M.: „A New Roof for the XIIIth Century "Loggia de Vicari" (Arqua Petrarca -PD - Italy) Based on Structural Glass Trusses: a Case Study‟, in Editor (Ed.)^(Eds.): „Book A New Roof for the XIIIth Century "Loggia de Vicari" (Arqua Petrarca -PD - Italy) Based on Structural Glass Trusses: a Case Study‟ (Tamglass, 2005, edn.), pp. 434-435

60.Belis, J., Van Impe, R., Lagae, G., Vanlaere, W., and De Beule, M.: „The underestimated structural role of elastic joints in glass beam applications‟, in Editor (Ed.)^(Eds.): „Book The underestimated structural role of elastic joints in glass beam applications‟ (Tamglas Ltd. Oy, 2003, edn.), pp. 767-768

61.Belis, J., Van Impe, R., De Meester, B., Lagae, G., and Katnam, K.: „Stability approach of the dimensioning of glass beams‟, in Editor (Ed.)^(Eds.): „Book Stability approach of the dimensioning of glass beams‟ (2004, edn.), pp.

62.Overend, M., Vassallo, C., and Camillieri, K.: „The design, assembly & performance of glass columns‟, in Editor (Ed.)^(Eds.): „Book The design, assembly & performance of glass columns‟ (2005, edn.), pp. 287-291

63.Núñez Díaz, M.Á., Cerezo Miguel, J.M., and Aguirregabiria, B.L.: „Prestressed glass beams‟, in Editor (Ed.)^(Eds.): „Book Prestressed glass beams‟ (2011, edn.), pp. 645-649

64.Pieplow, K.: „Glass meets new high-strength materials‟, in Editor (Ed.)^(Eds.): „Book Glass meets new high-strength materials‟ (International association for bridge and structural engineering (IABSE), 2008, edn.), pp. 346-347

65.Antonelli, A., Cagnacci, E., Giordano, S., Orlando, M., and Spinelli, P.: „Experimental and Theoretical Analysis of C-FRP Reinforced Glass Beams‟, in Editor (Ed.)^(Eds.): „Book Experimental and Theoretical Analysis of C-FRP Reinforced Glass Beams‟ (DEU, 2008, edn.), pp. 171-182

66.Cagnacci, E., Orlando, M., and Spinelli, P.: „Experimental campaign and numerical simulation of the behaviour of reinforced glass beams‟, in Editor (Ed.)^(Eds.): „Book Experimental campaign and numerical simulation of the behaviour of reinforced glass beams‟ (Glass Performance Days, 2009, edn.), pp. 484-487

67.Palumbo, M., Palumbo, M., and Mazzuchelli, M.: „A New Roof for the XIIIth Century “Loggia de Vicari”(Arquà Petrarca-PD–Italy) Based on Structural Glass Trusses: a Case Study‟, in Editor (Ed.)^(Eds.): „Book A New Roof for the XIIIth Century “Loggia de Vicari”(Arquà Petrarca-PD–Italy) Based on Structural Glass Trusses: a Case Study‟ (2005, edn.), pp. 1-3

68.Louter, P.C.: „High-strength fibre rods as embedded reinforcement in SentryGlas-laminated glass beams‟, in Editor (Ed.)^(Eds.): „Book High-strength fibre rods as embedded reinforcement in SentryGlas-laminated glass beams‟ (Glass Performance Days, 2009, edn.), pp. 285-289

69.Speranzini, E., and Neri, P.: „Structural Behavior of “Reinforced Glass”‟, in Editor (Ed.)^(Eds.): „Book Structural Behavior of “Reinforced Glass”‟ (Glass Performance Days, 2009, edn.), pp. 355-360

70.Speranzini, E., and Neri, P.: „Structural behaviour of GFRP Reinforced glass beams‟, in Editor (Ed.)^(Eds.): „Book Structural behaviour of GFRP Reinforced glass beams‟ (2011, edn.), pp. 604-609

71.Louter, C., Leung, C., Kolstein, H., and Vambersky, J.: „Structural glass beams with embedded glass fibre reinforcement‟, in Editor (Ed.)^(Eds.): „Book Structural glass beams with embedded glass fibre reinforcement‟ (2010, edn.), pp. 439-448

72.Veer, F.A., and Rodichev, Y.M.: „The structural strength of glass: hidden damage‟, Strength of materials, 2011, 43, (3), pp. 302-315

73.Vandebroek, M., Belis, J., and Louter, C.: „Influence of the load history on the edge strength of glass with cut edge finishing‟, in Editor (Ed.)^(Eds.): „Book Influence of the load history on the edge strength of glass with cut edge finishing‟ (IOS Press, 2012, edn.), pp. 587-596

74.Blandini, L.: „Structural use of adhesives for the construction of frameless glass shells‟, International Journal of Adhesion and Adhesives, 2007, 27, (6), pp. 499-504

75.Blandini, L., and Sobek, W.: „10 Jahre Stuttgarter Glasschale - eine Zwischenbilanz‟, Stahlbau, 2014, 83, (S1), pp. 77-86

76.Blandini, L., Sobek, W., Weller, B., and Tasche, S.: „10 jahre Stuttgarter glasschale - eine zwischenbilanz‟: „Glasbau 2014‟ (Wiley-VCH Verlag GmbH, 2014), pp. 77-86

77.Fröling, M.: „Strength design methods for laminated glass‟. Licentiate Dissertation, Lund University, 2011

78.Blandini, L.: „Prototype of a frameless structural glass shell‟, Structural Engineering International, 2008, 18, (3), pp. 278-282

79.Wurm, J.: „Glass structures: Design and construction of self-supporting skins‟ (Birkhäuser Architecture, 2007, 1st edn. 2007)

80.Petrie, E.M.: „Adhesion bonding: Intelligent adhesives and coatings that can multitask‟, Metal Finishing, 2009, 107, (11), pp. 41-44

81.Machalická, K., and Eliášová, M.: „Influence of various factors on mechanical properties of adhesive joint in glass structures‟, in Editor (Ed.)^(Eds.): „Book Influence of various factors on mechanical properties of adhesive joint in glass structures‟ (IOS Press, 2012, edn.), pp. 267-280