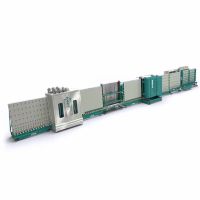

Analogous to industrial enterprises it is also particularly important for schools to get quality by means of modern and state-of-the-art machinery. After more than 20 years of use, the HTL Kramsach replaced the previous manually operated cutting table by a LiSEC „base CUT“.

After having compared different manufacturers in the market, the HTL quickly opted for the Austrian machine manufacturer. Originally known as an industrial brand for the high-end sector (regarding quantity, quality and price), LiSEC with its base series now provides relatively affordable machinery for newcomers in the industry, small-scale enterprises or the use in schools. For the headmaster, Dr. Ursula Pittl-Thapa, a former graduate of the polytechnic herself, the LiSEC cutting table was „Love at first sight“.

The students of the HTL Kramsach are working with the LiSEC cutting table since September 2015.

Established in 1948, the educational institution comprises a polytechnic for glass, the faculties glass and technology, glass and design as well as, for three years now, a HTL chemistry. The graduates of the HTL Kramsach, 361 students are educated at present, are very sought after in the glass industry and they cover a comprehensive spectrum of jobs, from the specialist for restoration up to the consultant in statics and façade engineering.

„The base beginner’s model is ideal for polytechnics and/or vocational schools in terms of price/performance and it provides “LiSEC quality at an affordable price”, says the native of Innsbruck who herself has processed glass for a while and who has “dragged around quite some glass sheets”. Due to the education purposes and the operation by inexperienced persons, the high degree of service of LiSEC constituted a critical purchase criterion when it came to the decision.

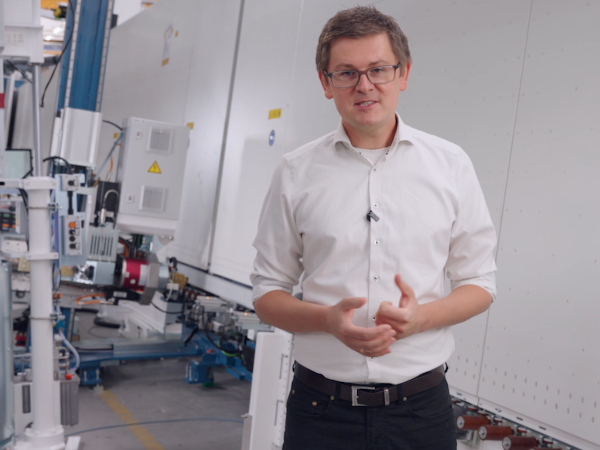

Klaus Preyler, LiSEC Sales Director, who handled the sale: „During their education, the students in Kramsach are now learning how to handle the best machines in the market– best in glass processing, from the outset!“

At the HTL Kramsach, the students are learning traditional as well as future-oriented processing techniques in order to exhaust the possibilities of glass as a material